We have just completed a machine control systems upgrade and machine safety upgrade on a wool sample cutting machine at a facility in Melbourne. The client had 3 machines with now obsolete equipment:

- Rockwell Kinetix 6000 servo drives

- Allen Bradley Compact Logix L30 PLC

- Allen Bradley Powerflex 70 VSD

The objectives of the control systems upgrade were to replace obsolete equipment with current versions, perform an updated machine safety assessment and take this opportunity to make machine performance improvements.

The solution was to design, install and commission a new control system utilising Compactlogix 5380 processor, Kinetix 6000 series servo drives, Powerflex 525 VSD and new safety equipment as dictated by risk assessment.

New electrical designs were completed, and the control panel modifications were done on site to reduce downtime. During the commissioning process all the axis were meticulously re-tuned as part of the process of replacing the servo drives leading to an improvement in performance in terms of cycle time.

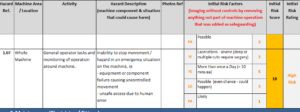

A total machine safety risk assessment was completed in accordance with AS4024 AS 4024, which identified that some existing categories were below what they should be, and certain devices were upgraded to the correct safety category level, and circuits redesigned and re-wired accordingly. See our other page for our machine safety services: https://coralprocesssolutions.com.au/services/machine-safety/

Coral Process Solutions were responsible for

- Electrical designs / drawings

- Machine safety risk assessment

- Machine safety upgrade

- PLC / HMI software

- Machine commissioning

- Servo drive tuning

- Training and operator manuals