Our engineers are chartered professional electrical engineers that hold national engineering registered (NER) status, EEHA training and are fully accredited in hazardous area design and classification, and we ensure that we are fully updated with changes to legislation. It is mandatory in most Australian states that electrical engineering tasks be completed by a registered engineer, and also AS 60079 states that hazardous area design and classification tasks be done by competent persons so our unique skill set allows us to provide a complete hazardous area solution.

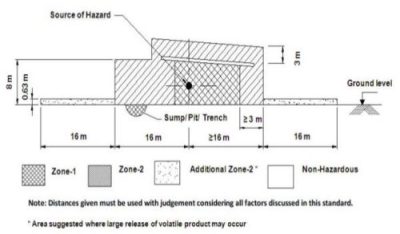

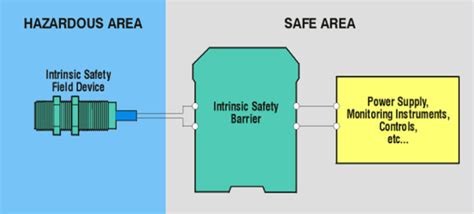

We specialize in hazardous area electrical installation designs and our engineers hold formal qualifications in hazardous area classification and design using AUS/NZ 60079 and international standards. Whether just adding a new sensor into a hazardous area to modify an existing process, or a complete new plant we are able to provide hazardous area classification, design and documentation.

We have completed projects in distilleries, printing, flammable storage facilities and agriculture in the classification of processes and plants with flammable liquids and dusts. Some projects are for complete engineering solutions but often we act as consultants to electrical contractors

Current Australian standards can be found at:

Standards & Legislation Store APAC – SAI Global Infostore

We will prepare complete hazardous area verification dossiers for projects, and as standard we will draft a hazardous area classification drawing.

Inspection of hazardous area installations prior to going live is mandatory under AS 60079 and through our partnership network of H class licensed inspectors, we are able to offer a complete design, build, install and sign off solution.

We can advise or create maintenance regimes for hazardous areas which are also vital to ensure ongoing safety of your plant and people.

Typically, the process involves initial discussion about the flammable or combustible substances in your process, the nature of the process itself and sharing of P&ID diagrams. We would then provide a budget price and arrange a site visit to review the plant (if it is built) and sources of ignition and get a much deeper understanding of the process. At this stage we may recommend changes to the process or plant if they are practical to reduce the possibility of explosion and reduce the cost of the hazardous area installation. We would then commence on area classification work.

If you already have the area classification and just require electrical engineering services, then this is also a typical project for us.