One of our many vision projects in the security printing industry is a label hologram inspection system. There is a labelling machine that produces holographic security images used in high end consumer goods, our project was to inspect these labels during the production process for any defects.

The unique challenge associated with quality inspection of holographic images is that the image by its very nature is dynamic and so deep learning vision inspection techniques were required for generation of the models.

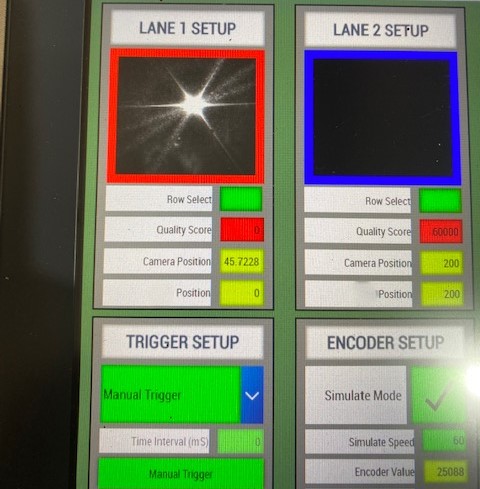

Training sets of good and bad quality holograms are created by the quality department using Beckhoff vision runtime packages. After creation of the inspection algorithms, inference times of 10ms were achieved.

The main processing was done with 3 Beckhoff Icore 7 industrial PC’s.

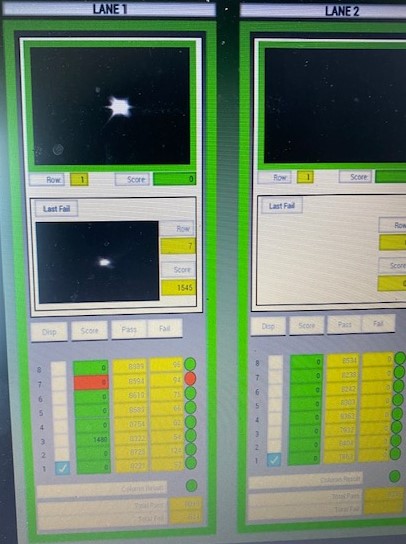

Operator interface was achieved with Beckhoff TwinCAT HMI package.

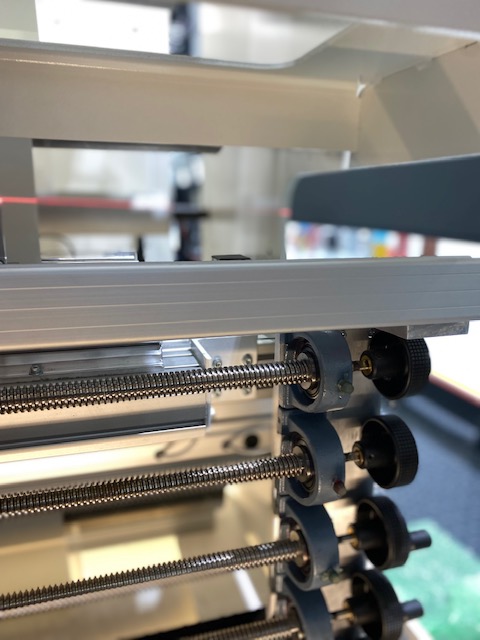

The solution consisted of 4 individual 640 x 480 monochrome area scan cameras mounted with leadscrews to facilitate easy modification of lane positions.

Using this technology has led to a dramatic decrease in false negatives and false positives consequently reducing waste.

The installed system provides 100% inspection of the production and every single hologram produced is inspected against a quality standard.