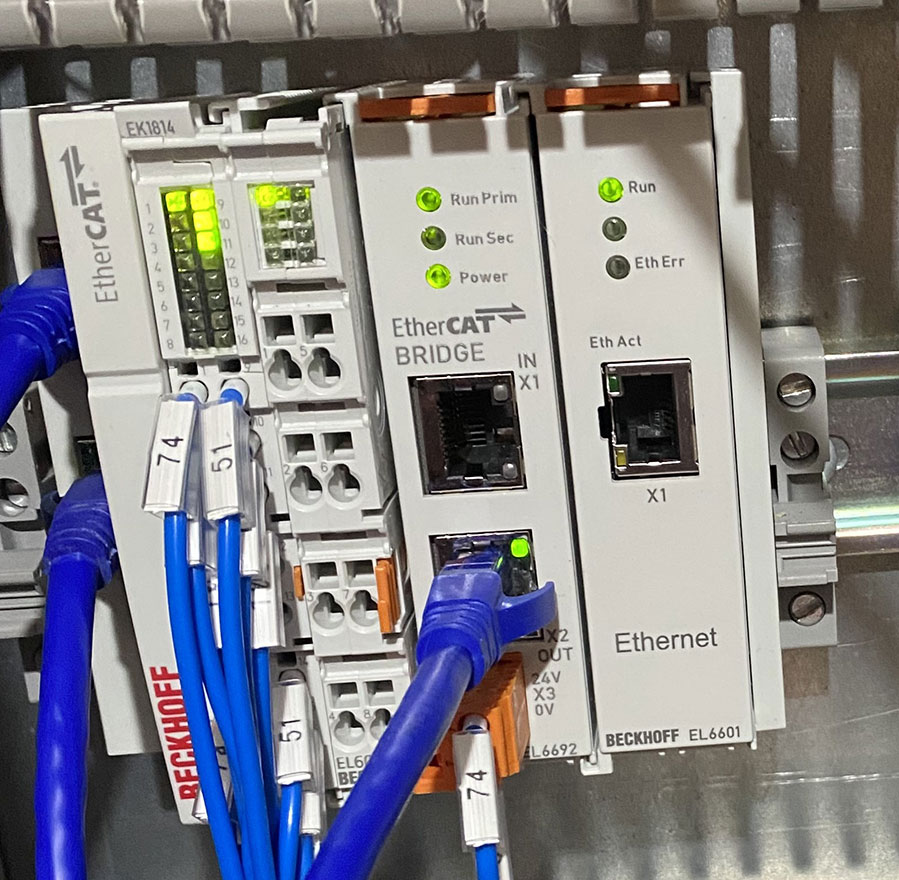

Our PLC programmers and controls engineers are available for contract or short-term support hire to assist in any Siemens, Rockwell, Beckhoff, Schneider PLC programming service support need that you have.

We can support in all aspects of control system engineering / automation engineering support:

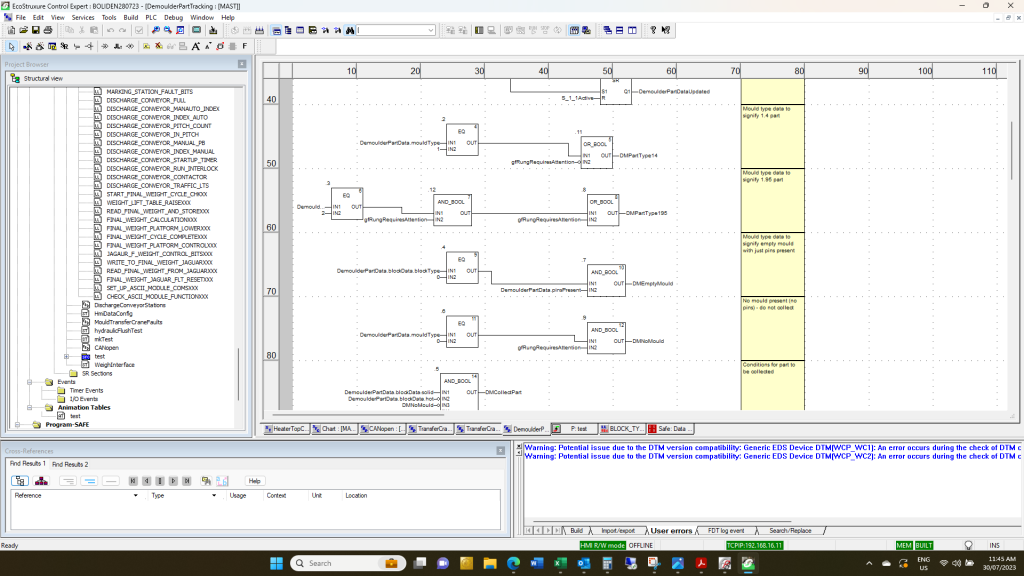

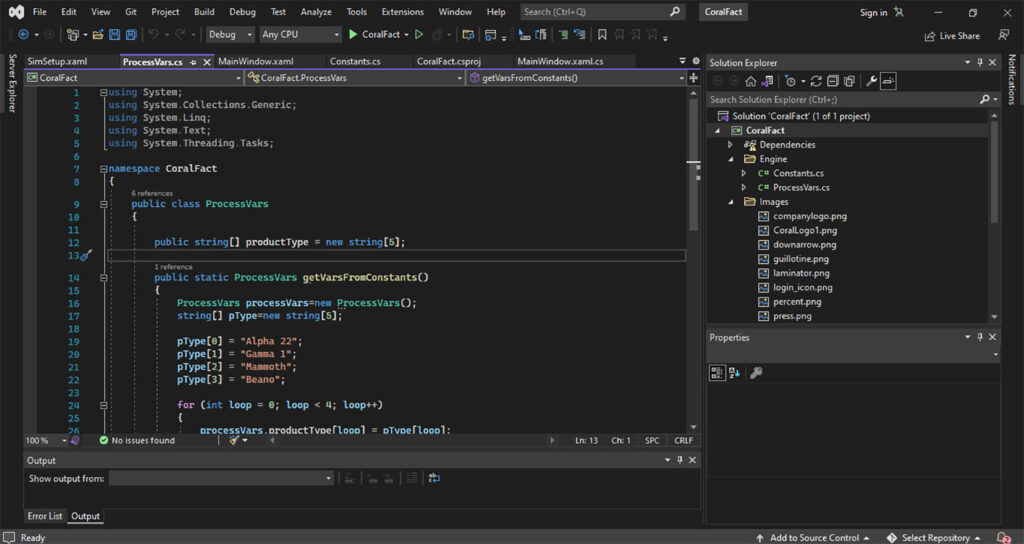

- PLC programming

- HMI design

- Motion control systems design

- Vision systems

- OT system design

- SCADA design

- Training

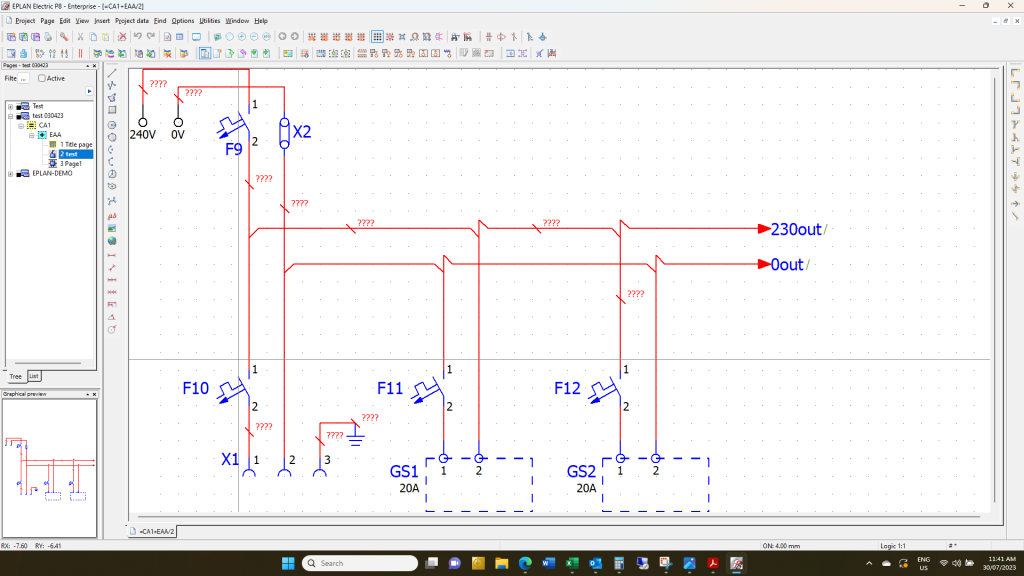

- Electrical design

- Control panel design

- Electrical drafting

- On site commissioning

Our PLC programmers and automation engineers have experience of all common PLC systems including, but not exclusively, Siemens, Rockwell, Schneider and Beckhoff.

We have hands on experience in most industry sectors and the individual unique challenges that they present, but typically this includes manufacturing, printing, security printing, food and beverage, pharmaceutical, airports, water treatment, building management, automotive, chemical process, power generation.

We are able to provide on-site and remote electrical design and CAD support using AutoCAD electrical, and EPLAN electrical CAD packages. Under Australian legislation any electrical engineering services should be undergone by registered engineers and our engineers hold all the credentials to do this work. Read more on our electrical engineering services on Electrical Engineering

We have decades of experience of motion control systems in the manufacturing sector using bespoke motion controllers, CNC systems and PLC based motion controllers, including some very challenging applications in terms of closed loop stability so we are well credentialed to undertake any motion control project that you have. Typically these systems have been machine tools, gantry systems, pick and place units, force measurement and other metrology solutions.

We specialize in machine vision and vision inspection systems, either standalone, or integrated into the PLC controller. See our other page for more information Vision Inspection Systems

Our PLC code is always written with future maintenance in mind and is well written, structured and documented. Our PLC programmers generally will try to use standard accepted good practice software techniques where possible (OOP etc) but will be completely guided by customer preference. Depending upon the application and customer preference we will write programs in ST, LD, SFC (or even FBD if that is your preference!) as defined in IEC 61131-3 IEC61131-3 Preview. Some examples of customer specific requirements are the ISA 88 batch control required in pharmaceutical and the message guided software specifications for sequencers used in the automotive industry.

Our experience in pharmaceutical applications means that we are aware of software techniques and methodologies used in GMP organisations.