We offer complete bespoke turnkey vision inspection systems solutions for quality inspection, measurement, product coding and product identification.

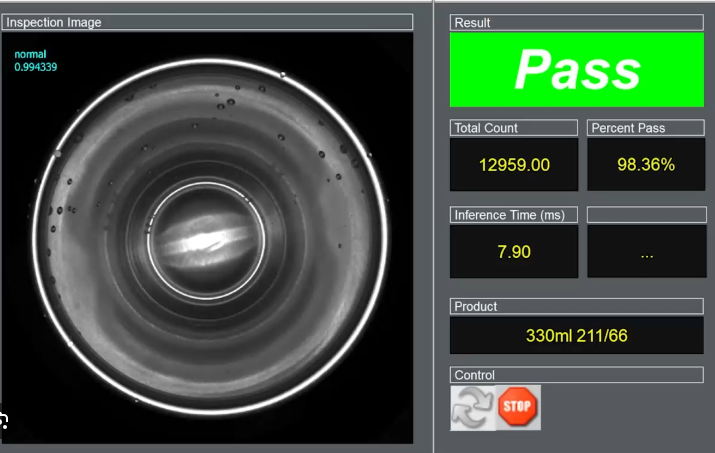

We are able to offer the latest technology in vision inspection systems solutions, including the latest AI deep learning methods as well as traditional rules-based systems, or a combination of both for model (template) creation.

Using any proprietary vision software package (Sherlock, Halcon, Beckhoff or bespoke) or using smart cameras if appropriate (Cognex, Sick) we will engineer a complete vision and HMI solution for any process.

Some further information on these packages can be found below:

TwinCAT Vision | Beckhoff Worldwide

We can engineer a vision solution for any size of project, from a simple single camera pass / fail application through to multi-camera multi networked solutions.

Interfacing to existing control systems is achieved by whatever method is appropriate using discrete I/O, fieldbus or other network protocols. With our control system knowledge – Automation control system and hazardous area design (coralprocesssolutions.com.au) – we are able to offer very strong complete engineering solutions.

We can integrate solutions for transfer and storage of images to central or dedicated servers.

We have particular experience in vision systems for high volume production processes which are time critical and have mastered many strategies for these applications in order to minimize inference times.

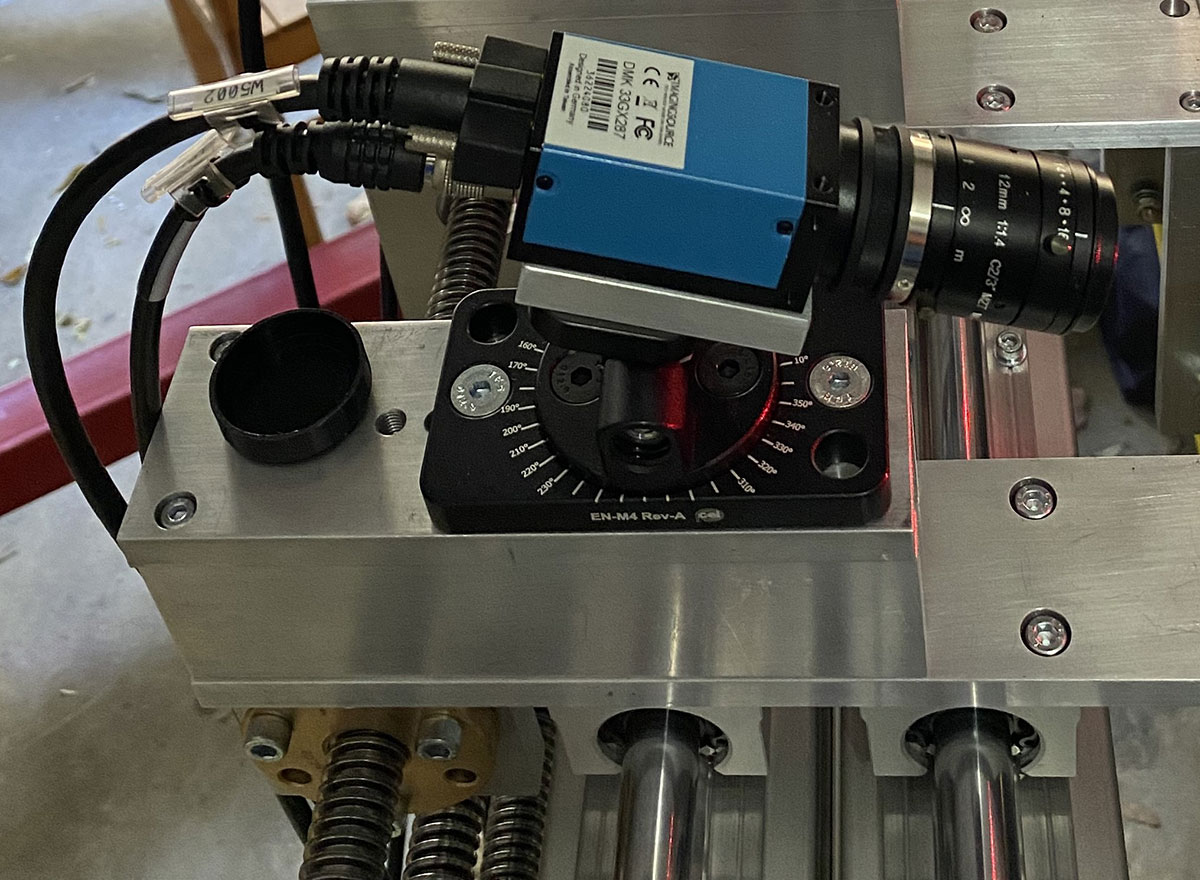

We design and build camera housings with both static and dynamic camera / lighting positions.

Previous projects include:

- Print process inspection system.

- Labelling OCR application.

- Casting quality inspection.

- Bar code position verification system.

See below for information about a Hologram Inspection system that we installed.

Contact us to find out what we can offer, and we can very quickly provide a summary solution.